Certified quality management system

Safety Tester

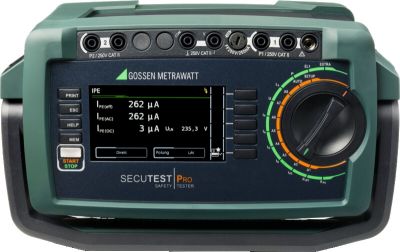

If you need to carry out electrical safety test in accordance with EN 60335, EN 61010, EN 60601, EN 60598 or other national and international norms, then you are at the right place. EN 60335 is a European regulation for safety of electrical devices. Tests in accordance with EN 60335; e.g. the protective conductor test, high voltage test and function test, are carried out on the whole device after assembly.

The robust, fully automatic Electrical Safety Tester ST400 ensures fast testing cycles incl. documentation (backtracking of data – Traceability). In addition to that, the ST400 Electrical Safety Tester also disposes two USB- Interfaces, LAN, RS232 and digital, as well as analogue I/O ports. I/O tests are ideally used to automatically pilot external systems. The test procedure with an Electrical Safety Tester results as follows: Connect the testee (device under test), chose the settings for the test program (automatic barcode if provided), test and save test protocol.

The Electrical Safety Analyzer can of course also be operated manually through a spin-press button, similar to GPS systems used in automobiles. The following operating modes are available: Manual, Remote RS232/USB, Digital and Ethernet. Each Electrical Safety Analyzer can be remote controlled through a comfortable testing software. The GOOD-BAD results will be saved automatically on your databank. Electrical Safety Analyzers will be delivered including a leakage current test in case the device needs to be used in accordance with the medical-technical norm EN 60601. The Electrical Safety Testers of the 60335 series are easy to integrate at the workplace and laboratory.

- X6 user interface

- Closed front without display

- PC with WIN 7

- LAN/USB interface included

- Compatible to all ST400 devices

- X8 user interface

- 10.4" TFT touch display

- PC with windows7 included

- LAN/USB interface included

- Compatible to all ST400 devices

- Easy setup of the system structure / measuring and storage / report generation

- Preconfigured and user programmable test sequences for testing electric systems quickly

- Storage concept for up to 50,000 data records

- Testing of all up-to-date AC/DC sensitive RCDs

- User safety by means of PE detection when using finger contact

- Selected accessories for pending measuring tasks

- Easy setup of the system structure / measuring and storage / report generation

- Preconfigured and user programmable test sequences for testing electric systems quickly

- Storage concept for up to 50,000 data records

- Testing of all up-to-date AC/DC sensitive RCDs, and many others

- User safety by means of PE detection when using finger contact

- Selected accessories for pending measuring tasks

- Protective conductor resistance measurement

- Insulation resistance measurement

- Leakage current measurements

Equivalent (alternative) method, direct method, differential method:

Protective conductor current, touch current

Device leakage current, patient leakage current, Leakage current from the applied part - Voltage measurement: Touch voltage, SELV, PELV voltage

- PRCD Time to trip

- Function test (U,I,P,S,LF,f)

- Conductor test: Continuity, short-circuit, polarity (wire reversal)

- Temperature measurement (for Pt100/Pt1000 sensor)

- Test device for DIN VDE 0100-600 / IEC 60364.6

- Loop and line impedance measurement

- Measurement of insulation resistance using nominal voltage

- Low-resistance measurement

- Earth resistance measurement

- Standing-surface insulation measurement

- Universal connector system

- Voltage from 65V to 500V

- Frequencies of 15.4Hz to 420Hz

- Automatic test sequence function

- Test device for DIN VDE 0100-600 / IEC 60364.6

- Loop and line impedance measurement

- Measurement of insulation resistance using nominal voltage

- Low-resistance measurement

- Earth resistance measurement

- Standing-surface insulation measurement

- Universal connector system

- Voltage from 65V to 500V

- Frequencies of 15.4Hz to 420Hz

- Testing of insulation monitoring devices (IMDs)

- Testing of residual current monitoring devices (RCMs)

- Protective conductor resistance measurement

- Insulation resistance measurement

- Leakage current measurements

- Equivalent (alternative) method, direct method, differential method:

- Protective conductor current, touch current

- Device leakage current, patient leakage current, Leakage current from the applied part

- Voltage measurement: Touch voltage, SELV, PELV voltage

- PRCD Time to trip

- Function test (U,I,P,S,LF,f)

- Conductor test: Continuity, short-circuit, polarity (wire reversal)

- Temperature measurement (for Pt100/Pt1000 sensor)

- All-Round-Test-Cage to connect

with safety testers and hipot testers - Dimension (W/H/D):

Outside: 450 / 515 / 495 mm

Inside: 360 / 350 / 450 mm - Viewable transparent swinging hood

- Damping gas spring

- Safety limit switch

- CE conform with EN 50191

- All-Round-Test-Cage to connect with hipot tester ST9200er series

- Dimension (W/H/D):

Outside: 450 / 515 / 495 mm

Inside: 360 / 350 / 450 mm - Viewable transparent swinging hood

- Damping gas spring

- Safety limit switch

- CE conform with EN 50191

- Including cable set for hipot tester 36 series

- Dimension (W/H/D):

Outside: 450 / 515 / 495 mm

Inside: 360 / 350 / 450 mm - Completely mounted and wired for plug&play

- PVC design-housing

- Viewable transparent swinging hood

- Damping gas spring

- Safety limit switch

- CE conform with EN 50191

- Including cable set for safety tester ST400 series

- Dimension (W/H/D):

Outside: 450 / 515 / 495 mm

Inside: 360 / 350 / 450 mm - Completely mounted and wired for plug&play

- PVC design-housing

- Viewable transparent swinging hood

- Damping gas spring

- Safety limit switch

- CE conform with EN 50191

- All-Round-Test-Cage to connect

with safety testers and hipot testers - Dimension (W/H/D):

Outside: 670 / 515 / 495 mm

Inside: 565 / 350 / 450 mm - Viewable transparent swinging hood

- Damping gas spring

- Safety limit switch

- CE conform with EN 50191

Process of Testing with a Safety Tester

The testing process with a safety tester is as follows: connect the test object once, select the test program (optionally automatic via barcode), perform the test, and store the protocol data. Of course, the VDE test device can also be operated manually using the rotary-push knob – just like using a GPS in a car.

Modular Configuration of Your Safety Tester

As previously mentioned, electrical safety tests must be carried out in accordance with standards. Each standard defines a specific test setup that must be followed when testing a device under test. Since these setups can vary greatly, Sourcetronic offers you the option to configure your own measuring instrument. With a wide range of test modules such as high voltage, insulation, protective conductor, leakage current, and functional test, you can perform almost any standard-compliant test according to VDE, EN, or UL. Configure your own ST400!

Support for Different Operating Modes

The operating modes Manual, Remote RS232/USB, Digital, and Ethernet are available. With the convenient test technology software, you can remotely control any VDE test device. The PASS–FAIL results are automatically stored as XML files in your database. For the medical standard EN 60601, you receive the VDE test device with leakage current testing. Whether in the workshop, laboratory, or serial production, the 60335 safety testers can be integrated quickly and easily.

Product Overview: Buy Safety Testers