PID control

Basics of PID control

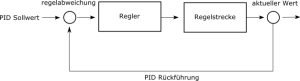

A PID controller is a control structure that attempts to adjust a specific controlled variable (pressure, temperature, etc.) to a specified setpoint (PID setpoint). To do this, the controller needs information about the current status of the system in the form of a measured value (pressure sensor, temperature sensor, etc.). This signal is called PID feedback.

This control structure usually has three components: P = Proportional, I = Integral and D = Differential.

How is it regulated here?

In the picture you can see that the PID feedback value is subtracted from the PID setpoint. The difference signal is generated from this. If the two values are equal, no correction is necessary and the frequency inverter will not change its frequency. If the PID reference is greater than the feedback value, the difference signal is positive and the frequency inverter will increase its output frequency until the PID reference and the PID feedback value are equal. Thus, the frequency is continuously adjusted as long as there is a difference between the PID reference and the PID feedback.

Simple example:

PID setpoint equal to PID feedback ==> no change of frequency at the inverter

PID setpoint greater than PID feedback ==> increase of frequency at inverter

PID setpoint smaller than PID feedback ==> decrease of frequency at the inverter

Effect of the individual parts of the PID control

P – Share:

The P component is the proportional component, which means that the effect depends only on the momentary difference between PID setpoint and PID feedback. However, the disadvantage is that the closer the setpoint and feedback get to each other, the smaller the correction becomes. This slows down the control response. In theory, the setpoint is never reached.

I – Share:

The I component can solve the problem of not reaching the setpoint from the P component. The I component integrates the difference between setpoint and feedback. Even with small differences, after some time the correction signal becomes large enough to correct the error between PID setpoint and PID feedback.

D – Share:

The D component solves another problem of the P controller. Since the correction signal can never be greater than the difference between the PID setpoint and the PID feedback, the D component can briefly amplify this difference and thus accelerate the response of the controller. However, this is only recommended if a good control response is not achieved with the P and the I component.

« Back